Rubber

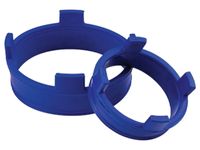

Molded Rubber, Neoprene & Silicone Parts

Caplugs offers molded rubber products using material created using our engineering team’s advanced compound mixing capabilities. Components are created with various synthetic rubbers including ethylene propylene diene monomer (EPDM) and neoprene. Material development and mixing is all done right at our plant, and we offer products made with NBR, FlexTemp (thermoplastic rubber), medical-grade elastomers and other materials.

Show more

Our facility is IATF 16949 and ISO 14001 certified, and our custom rubber parts and application-specific rubber components provide the strength and flexibility you need for masking, product protection and many other high-temperature applications in automotive, industrial, HVAC and many other industries.

Material Benefits

- Withstand temperatures up to 350°F (177°C)

- Low-cost and customizable solution

- Abrasion resistant for blasting applications

- EPDM resists alkalis, acids and oxygenated solvents

- Neoprene offers maximum durability

- Ideal for plating and wet paint finishing

Processes

- Injection molding

- Compression molding

- Transfer molding

Free Samples

Available on all standard parts

Product Availability

Products will be shipped as soon as available if not in stock