We’ve all heard the phrase a well-oiled machine when describing a successful business or sports team – something that’s operations have been perfected over years of careful oversight, now seen as a leader in its given field. It is also a perfect description for injection molding.

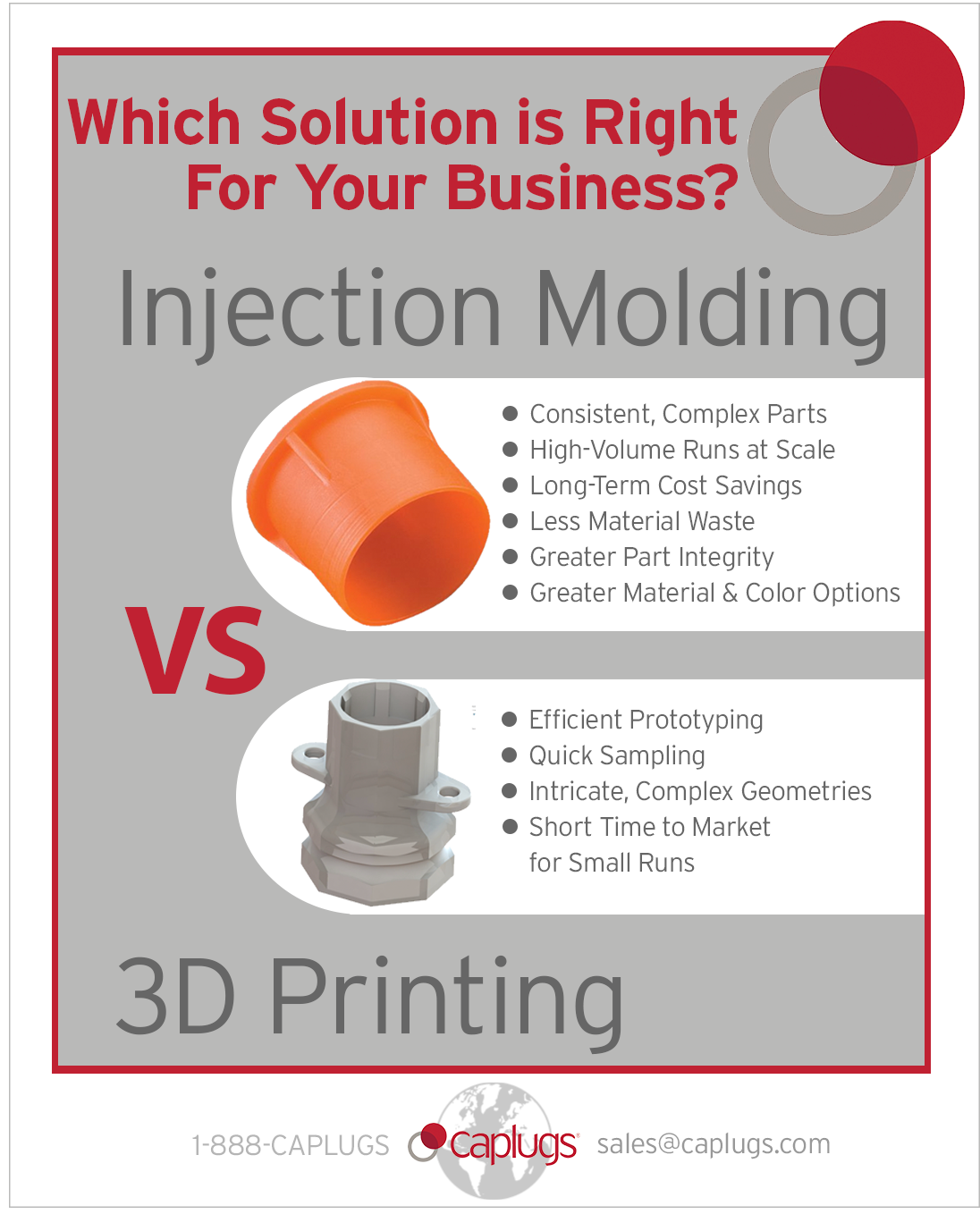

While injection molding has been seen as the standard bearer for the manufacturing of plastics for years, a new competitor has joined the fray, with 3D printing becoming a popular option of late.

3D printing has brought about new possibilities for businesses of all sizes, especially when it comes to prototyping and modeling, but there are certain areas where it simply cannot compete with tried-and-true injection molding processes.

When it comes to selecting one of these production methods for your business, it’s important to review the pros and cons and ask the necessary questions. We will look to do that here, in the hope of finding the right process for your business, whether that be injection molding, 3D printing - or both.

Injection molding is an automated manufacturing process that involves the melting of thermoplastic pellets to form a range of plastic parts, including everything from plastic bottles to children’s toys, protective products and more.

The manufacturing process involves the use of hot and cold runners that aid in the flow of the melted thermoplastics, moving them from the top (nozzle) of a molding machine to the tool’s cavities where plastic parts are shaped, cooled and ejected.

Plastic injection parts offer strength, making them an ideal option for the protecting of products. They can also feature material additives such as chemical, UV and thermal resistance. This strength and availability of additives allow injection molded parts to stand up to rough environments and chemicals that can often damage other protective options.

Companies across industries such as automotive, aerospace and electronics rely on mass-produced parts to protect equipment and keep operations running smoothly. Many want to leave nothing to chance when protecting their investments, but providing comprehensive protection can often require complex, customized parts. When consistency and complexity are top of mind, they will trust injection molding above all other manufacturing methods.

Injection molding’s consistency comes in part from initial leg work done in the design phase. Complex CAD designs are created and reviewed, and functional testing such as mold flow analysis is completed. These steps allow for changes to be made before final tooling is created, and ensure products are manufactured without part imperfections.

When the tool is approved and built, consistent parts will be manufactured at scale and to spec, with each part being essentially identical. This delivers an efficient and consistent solution to a customer’s needs.

Injection Molded Parts Made at Scale

Anywhere from a single cavity to hundreds of cavities can be built on a single injection molding tool. This allows for many parts to be made during a single manufacturing cycle. With cycle times taking less than a minute on average, one can see just how quickly high volumes of injection molded parts can be created.

Once a cycle is complete, plastic parts get ejected from the mold and can quickly be packed and shipped to customers for use.

Upfront tooling costs often create a perception that injection molding is a costly option, but that cannot be further from the truth in most scenarios.

While tooling cost is certainly something to account for, it is typically paid back quickly if high volumes of parts are being produced. Paying for a tool also means the customer has ownership of it and will be saving each time a part gets made on their tool (compared to buying a catalog part at market price). Companies that mass produce parts will quickly pass a savings threshold, with the overall piece price going down with each part they manufacture.

This makes injection molding an ideal long-term option and a more cost-effective approach when producing thousands upon thousands of the same part over many years.

Injection Molding Machine In Use

These injection molded parts create less material waste compared to 3D printed parts. They also offer little to no post-production requirements or scrap (especially with hot runner machines), making it a more sustainable manufacturing process while also requiring less labor.

Injection molded parts have a single, uniform material layer that provides greater part integrity and greater resistance to mechanical stress and impact. They can also be made in different colors for greater organization and visibility.

Injection molding is often used in concert with 3D printing during the prototyping stage. This can further improve processes and lead times, and save companies valuable dollars in the early stages of a project.

Startup costs can be higher compared to 3D printing because of the tooling required, but as mentioned above, these costs are quickly recouped when producing parts at higher volumes. Insert stacks can be explored as an alternative to full-tool builds as well, making injection molding tooling accessible for all budgets.

Design and prototyping for standard injection molding can take anywhere from two to six weeks. More complex tooling can take roughly eight weeks to build. While this is longer than 3D print prototyping, 3D prototypes can often be used for injection molding projects to improve lead times.

Injection tooling isn’t the most economical option when only a few parts are required. In this instance, 3D printing can be a prudent alternative, as you can get a few parts made without purchasing a tool. Should you prefer the quality of injection molding, sample kits are available in lieu of short runs on a part.

3D Printed Parts

3D printing is an additive printing process that is commonly used for the prototyping and manufacturing of intricate parts. This method allows for the printing of a range of designs on a single machine, without the need for complex tooling. A 3D printer creates parts layer by layer from a digital rendering.

This process can produce stiff, semi-flexible and elastic parts based on need. Common 3D printing processes include stereolithography (SLA), fused deposition modeling (FDM), selective laser sintering (SLS), digital light processing (DLP) and multijet fusion (MJF).

A major benefit of 3D printing is the ability to create prototypes quickly, with less intricate prototypes taking as little as a few hours. This allows for samples to get into a customer’s hands quickly and gives them the option to move forward with manufacturing or make further design changes. A new prototype or tweak to an already approved part can be completed with little downtime or extra cost.

While there are many positives to 3D print prototyping, it should be noted that larger prototypes or those made with greater detail can take longer to be sampled (usually completed in a few days).

One of the biggest advantages of 3D printing is its ability to produce more intricate geometries that are difficult to achieve with injection molding. Because of layering methods, even the most unconventional designs can be brought to life.

Small Runs with Intricate Capabilities

Since 3D printing typically involves low-volume production, parts can be manufactured and delivered to customers quickly. Small runs can be completed in a week or two depending on the complexity and size of the part(s). If larger runs or exceedingly complex parts need to be made, lead times can grow, making it ideal to use a 3D printer for small plastic parts.

While small runs of 3D printed parts can have a shorter time to market, this timeline gets pushed out when higher volumes are needed. This is because of 3D printing’s longer cycle times.

Where an injection molding cycle can take roughly a minute and produce upwards of 100 parts, 3D printing cycle times can vary drastically, from 30 minutes to a day based on the size and detail of the part. This is in addition to 3D printing being limited to producing one part (or two smaller parts with certain machines) at a time. Because of this, 3D printing is typically suggested when 100 parts or fewer are required.

One of the biggest detractors of 3D printing is the quality of the part itself, often having less strength and impact resistance, as well as greater consistency issues.

Many 3D printers, especially lower cost models, have difficulty creating precise parts consistently. When coupled with the fact that malfunctions or misalignments are common in lower-grade models when layering, it is not recommended when exacting parts are required. High-end printers can provide better results, but they come at a price point more comparable to injection molding.

As an example, more expensive SLA printers offer tighter tolerances within ±0.001 to ±0.003 inch per inch, making them suitable for parts requiring fine detail. However, FDM printers provide tolerances in the ±0.003 to ±0.006 inch per inch range, which can leave imperfections like visible lines and excess materials on the part.

3D printing is more limited in terms of material selection compared to injection molding. Based on the printer selected, only a few material options may be available. In contrast, there are often hundreds of common injection molding plastics with several different material additives to choose from.

It's important to note that some materials may not perform well when run through a 3D printer. Materials like acrylonitrile butadiene styrene (ABS) and nylon will generally print well in an FDM printer, while materials like polyethylene (PE) and polypropylene (PE) can create warped parts going through the same printer.

Imperfections such as flaking, misprinting and visibility of layers and lines are often seen on 3D-printed parts. If these are not cleaned up before application, they can cause serious damage to products. These imperfections can be cleaned up and smoothed out but will require more time and extra labor.

While some 3D printers can be less expensive than injection molding tools, high-quality machines capable of producing consistent, detailed parts have a comparable price to injection tooling. Additionally, the long cycle times (sometimes up to 24 hours per part) can lead to increased electricity usage.

When deciding between 3D printing and injection molding, there isn't really a "winner" to declare – it's about partnership and choosing the right tool for the right job. The best choice depends on your production needs, how many parts you require, the level of precision and how fast you need them.

For quick, small, and rapid prototyping or small runs, 3D printing is your go-to solution. It's ideal for low-quantity runs, intricate part designs, or when you need to move quickly through prototyping and development.

For precision, strength, consistency, and volume, injection molding takes the lead. It's the best choice when you're looking for high-volume production with tight tolerances and consistent quality. It's hard to beat when it comes to repeatability and long-term cost efficiency.

These solutions can also work in concert, with 3D printing often being used in conjunction with injection molding to help refine designs before committing to full-scale production.

If you're weighing your options or looking for custom plastic components, our team is here to help. We have fast, economical project management to guide you through the process and to get you up and running faster than anyone in the industry, with 24-hour turnaround on custom quotes.

We invite you to reach out at 1-888-CAPLUGS to speak with a team member. You can also reach out at sales@caplugs.com or request a quote. We’ll be happy to talk through your project ideas whenever you're ready.