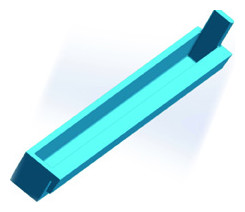

Background: The customer, a global auto parts manufacturer and major supplier of HVAC systems for automotive applications, was in need of a complex, custom masking solution for a condenser mounting rail. The customer was looking for a supplier with the right molding capabilities, who could also meet their aggressive timeline and provide a cost-effective solution.

Challenge: the customer needed to mask a bar code label, located on a u-shaped condenser mounting rail, during paint application. It was important that a bad code remains visible and functional after painting, to maintain traceability and control inventory from the plant to the end-user. Additionally, the mask needed to stay in place during the painting process.

Solution: Caplugs designed a custom silicone masking insert with an operator friendly removal tab to press fit into the mounting rail, and an overhanging lip for extra friction to help hold it in place.

Background: A medical technology company that serves healthcare institutions, life science researchers and clinical laboratories with a range of medical supplies, devices, laboratory equipment, and diagnostic products.

Challenge: An automated microbiology system used in epidemiology studies has two identical openings that needed a closure that could be both easily removed and tight fitting, it allow ease of access in the lab as well as ensuring contents did not spill when closed. The plug seals needed to be right enough to ensure that once the unit was placed in a centrifuge it remained intact. The plugs needed to be produced under tight cleanliness guidelines and automatically packaged in an easy open package to allow no direct handling of the parts.

Solution: Caplugs designed a custom injection molded plug that could be easily snapped into place once the test was initiated, ensuring a tight fit. Produced and packaged in an ISO Class 8 cleanroom, the plugs adhered to their stringent cleanliness requirements and was tight enough to ensure the contents wouldn’t spill.

Background: A medical device company that provides technologies for clinicians for safe eternal feeding, lavage and vascular therapy.

Problem: When suctioning gastric drainage from patients, home healthcare workers might accidentally from the port cap, causing contamination that could affect the patient or healthcare worker. The customer approached Caplugs looking to develop a cap with a “leash” to attach to the valve.

Solution: Caplugs’ Engineers developed a unique custom vinyl tether with a two headed cap that met the functional needs of the clinician as well as the homecare patient. The cap fits both the ports despite the slightly different diameters as the vinyl material allows some flexibility. The funnel connector and plug are also molded by Caplugs.

Background: Diagnostic based medical device manufacturer that supports laboratories, doctor’s offices and hospitals – a full continuum of healthcare.

Challenge: Customer used an open vial containing a reagent leaving risk of spillage during secondary processes. They evaluated use of various materials such as covers and plugs, as well as standard protective plugs with little success. Further challenges resulted as the customer sought to automate the secondary process of inserting a medium into the vial. Material requirements included gamma stable, non-toxic, FDA grade.

Solution: Caplugs Engineers designed a custom injection molded PVC plug with shut off. Customer was extremely pleased, noting increased efficiencies and reduced rework.