Have you ever been watering your lawn or garden and suddenly notice a leak shooting from your hose? Most of us have been there and know the time and energy required for finding a solution.

Imagine that same scenario happening in an industrial or commercial setting with hydraulic hoses. Only this time it’s not water shooting out, but potentially dangerous materials or chemicals.

For those who own and operate heavy machinery with hydraulic hoses, a backyard DIY glue-and-tape job won’t do the trick. You’ll need something that can stand up to potentially intense pressure and tough working conditions.

This is where hydraulic hose protection comes in. While there are many different types of hose protection on the market, such as spiral wraps, we will focus on hose protector sleeves in this piece, as they are considered the industry standard when protecting larger industrial hoses like those used on hydraulic equipment. Here, we will dive into two of the more popular hose sleeves on the market and show you why one is the clear choice when it comes to protecting valuable hoses and other equipment, while simultaneously being a more economical material option.

A hose sleeve, a piece of durable material that can be slid over a hose, protects against common issues like pinhole leaks and bursts that can cause damage to equipment and employees.

Aside from burst and leak mitigation, these sleeves can prevent damage from fires or chemical spills, and less dangerous but potentially costly issues like abrasion, moisture and UV damage when hoses are exposed to the elements.

These protective sleeves are available in a range of sizes based on need and are available in different material options, with polyester and nylon being the two most common.

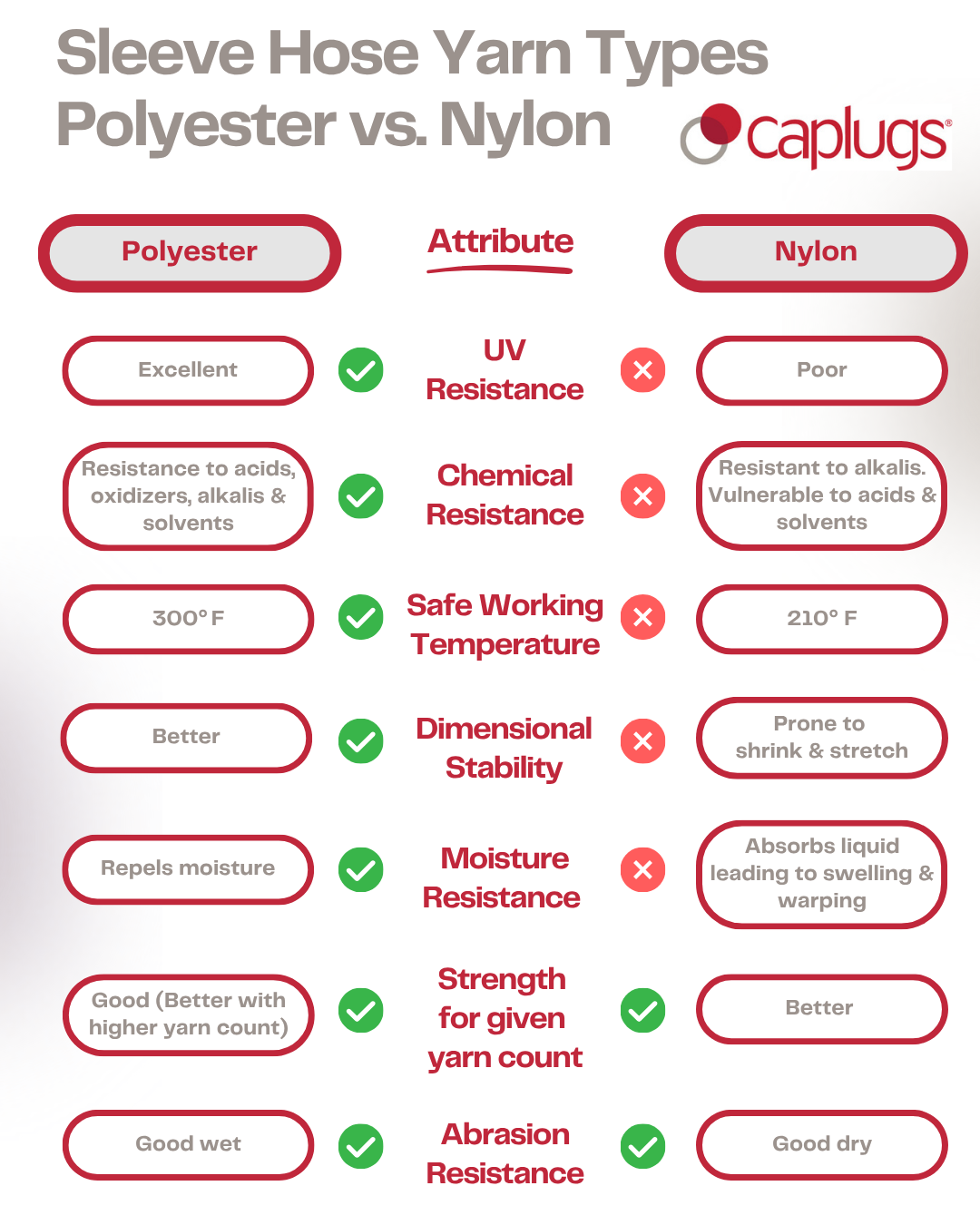

While some companies express a preference for nylon based on past experience, side-by-side testing and data consistently shows that polyester offers a range of advantages that makes it the superior choice. From performance and durability to safety, the facts speak for themselves.

It is important to note that polyester and nylon can each provide quality, reliable hose protection to a point — but going beyond that point is where the differences start to become clear.

When creating polyester hose sleeves, narrow fabric (also known as high tenacity polyester yarn) is used for weaving, helping create a reliable product that can stand up to a variety of pressures.

Polyester hose sleeves can weave a higher yarn count than nylon when required, allowing it to better stand up to bursts and pinhole leaks. Due to its higher yarn count, polyester sleeves are MSHA approved and commonly used for mining operations where reliable hose protection is a necessity.

While polyester provides strength in its higher yarn count, it should also be noted that nylon offers better strength when yarn count is identical.

Below, we'll take an even closer look at why polyester is the clear choice for reliable, long-lasting hose protection.

Hydraulic hoses are built to withstand pressure and intense forces, but they are still susceptible to being damaged. In operations such as mining, hoses are frequently exposed to high water or fluid pressure, increasing the risk of bursts and pinhole leaks. To prevent these bursts and leaks from causing greater damage, hose sleeves are often placed around hoses, allowing for the burst or leak to be contained more safely and with less pressure.

Both nylon and polyester hose sleeves can ease the pressure of a rupture in certain environments, with polyester proving to be more effective at relieving pinhole leaks and hose bursts at higher pressures.

In pinhole testing conducted by our team, the competitor’s hose sleeve allowed a pinhole leak to rip through the nylon material, while the polyester sleeve contained the pinhole leak and safely released the fluid through various parts of the weave with little to no pressure.

In burst testing, we found a hose will burst at 400 bar/5,800 PSI. When we retested at the same amount of pressure with the competitor’s nylon sleeve attached, the sleeve did not hold up, bursting at its ends when it attempted to relieve the pressure of the burst.

When we tested a higher thread count polyester sleeve at the same pressure, the polyester did not burst and safely released liquid out the ends of the sleeve without damage. Further testing was done on the polyester at 700 bar/10,150 PSI, with it again safely relieving liquid out the ends of the sleeve, with no visible damage to the sleeve itself.

The higher thread count and greater density achieved in polyester’s weaving allowed for this success, and for it to retain its shape after testing, where nylon ballooned and eventually burst.

While nylon and polyester are both flammable materials, a fire-retardant coating can be added to create self-extinguishing properties.

Many hose protection companies claim to have a fire-retardant coating on their sleeve products, however, our flame retardancy tests have proven otherwise. It is our experience that many sleeve manufacturers (including nylon manufacturers) fail to stand up to performance standards in this area.

To ensure our polyester hose protection sleeves do not succumb to this, they are dipped in fire retardant chemicals then rung out with a nip roller. We then dip the sleeves in the chemical for a second time and ring them out again, providing a thick coat of fire-retardant material that nylon manufacturers typically don’t match.

This coating obviously becomes extremely important when a hose fire occurs, either from the chemicals being housed, from static charges or for any other reason. Where a polyester safe sleeve can self-extinguish a flame in roughly 30 seconds, a competitor’s nylon sleeve will continue to burn long after the 30 second mark.

If you’re curious about the safety of your hose sleeves in this area, we would be happy to take a sample from your current stock and run testing compared to our polyester hose protection.

Similar to flame retardancy, both polyester and nylon have no natural conductivity or anti-static properties. However, anti-static/conductive threads are available and can be woven into polyester hose sleeves as needed. This can be extremely useful in certain industrial applications, such as underground mines, where static discharge can potentially ignite explosive materials. Polyester sleeves with anti-static or electrical conductivity properties allow for static charge to ground at the ends of the sleeve instead of building up and being left open to these potential dangers.

Our electrical conductivity testing, done in accordance with ISO standard 8031, found that the polyester sleeve met MSTC standards and prevented the buildup of static, while the competitor sleeve failed the test, having no anti-static capabilities.

While we have shown that polyester either outperforms or performs similarly to nylon in a number of key areas, it is equally important to note it is a more economical option when comparing the material cost of each.

This may not be a determining factor for some companies who have used nylon for years and only order in low volumes, but it can become important when high volumes of hose sleeves are required to keep projects running smoothly.

Polyester hose sleeves can provide greater dimensional stability by offering a higher thread count and density. This is important for hoses that are regularly exposed to elements like fluctuating temperatures, moisture and humidity. Where nylon is prone to stretch and shrink in these conditions, polyester will typically retain its shape.

This not only provides more precise and consistent protection for critical hoses but can potentially increase the life of the sleeve.

In addition to environmental durability, it will probably come as no surprise that polyester hose sleeves perform well under prolonged exposure to sunlight. They are a great option for hoses used in warmer climates or those exposed to sunlight throughout the year, as polyester sleeves can maintain their strength and color over prolonged time in the sun.

Nylon, on the other hand, is more vulnerable to UV degradation and can become brittle with prolonged sun exposure. While it isn’t naturally suited for high-UV environments, nylon hose protection sleeves can be treated with UV stabilizers to improve their performance —but even then, they typically fall short of polyester’s long-term durability under harsh sunlight.

Polyester is inherently more hydrophobic (repels water better) than nylon and dries significantly faster. This makes it a smarter choice for environments where hoses are regularly exposed to moisture or high humidity.

In contrast, nylon can absorb up to 10% of its weight. While this can potentially be helpful when there is minimal hydraulic fluid leakage, it can also lead to swelling, warping and a decline in protection over time.

If your operations take place in wet or humid conditions, polyester hose sleeves offer a more reliable and longer-lasting solution.

Polyester offers higher resistance to several chemicals including acids, oxidizers, alkalis and organic solvents, making it a more chemically stable and durable option overall.

While nylon also performs well against alkalis, it is significantly more vulnerable to degradation when exposed to acids and certain solvents.

Where chemical exposure is a concern, polyester provides a higher level of long-term protection.

Polyester hose sleeve protection provides further advantages including:

When it comes to protecting hoses in demanding environments, polyester hose sleeves stand out as the clear choice.

With superior burst and pinhole protection, greater fire resistance, and anti-static and electrical conductivity capabilities, polyester outperforms nylon in real-world applications— all while being a more economical option.

Should you be interested in learning more or are ready to make a purchase, our team is standing by to assist. We have polyester hose sleeves in stock and ready to ship today, with branding and customization available upon request.

Still unsure? Send us a sample of your current hose sleeve, and we’ll be happy to conduct a side-by-side video test similar to the ones seen in our safety videos above. Our products are continually and consistently tested to ensure we exceed expectations and keep the end users safe.

When you require quality and reliable performance, all while meeting stringent safety specifications, we invite you to contact us to make the switch to polyester hose protection.