Selecting the right packaging protection ensures that your product makes it where it needs to be free of damage or contamination. So how do you make the right choice? Let's explore your options.

Packaging protection is a critical component of any product’s journey from the manufacturer to the distributor, wholesaler, retailer or end customer.

The right packaging provides extra protection and ensures that products arrive in good condition, free from damage and contamination.

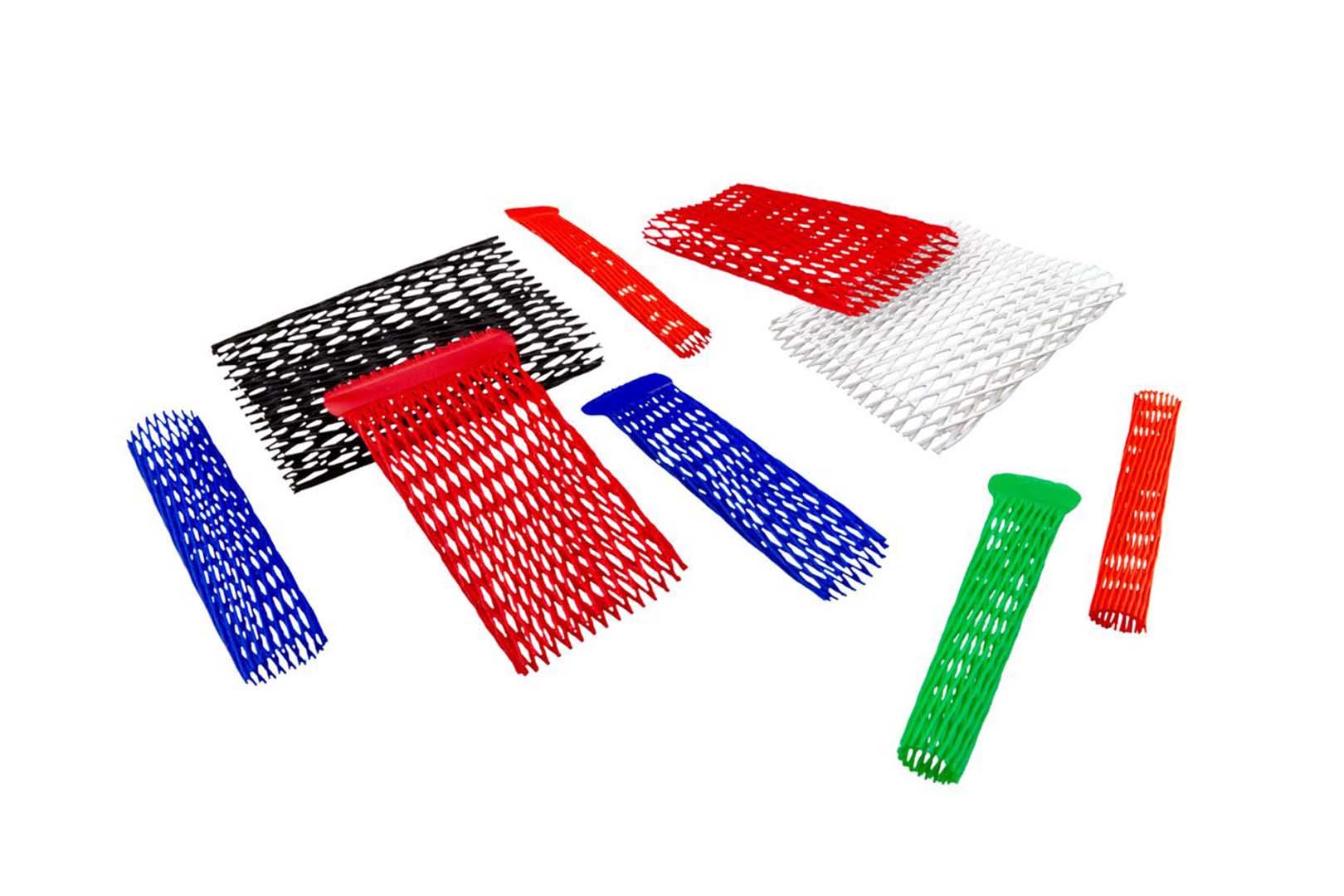

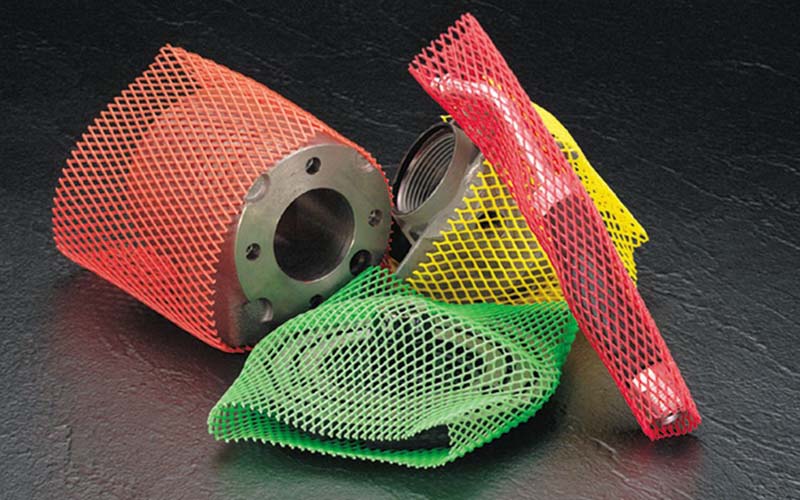

Packaging material made from plastic fibers or strands that are knitted or woven together to form a net-like structure.

Hollow extruded plastic tube used to transport products and/or serve as a display for retailing.

Containers of all shapes and sizes used to store a variety of products across all industries.

Packaging specially designed for medical products, such as pharmaceuticals, medical devices and diagnostic products.